By | Julia Kesprov

If you want to improve your manufacturing processes, there are a few things you can do. In this blog post, we’ll share 6 tips that can help make your manufacturing more efficient and effective. Keep reading to learn more!

Understand Your Customer’s Needs and Requirements

A business’s success hinges on its ability to understand what its customers want and need. Whether it is a product or service, understanding your customers’ needs helps you to provide them with the best experiences that they can have.

It’s important to think beyond the transactions and identify any underlying needs of your customer so that you can truly meet their expectations. Collect data and feedback from past customers so you can better understand how they felt about the experience.

Ask questions, listen to their responses, and even observe their interactions with a product or service. This in-depth understanding can help you tailor content for each customer, making sure it fits their circumstances and appeals directly to them.

By Aligning your efforts around your customer’s needs, you can ensure that whatever you offer is always crafted with excellence in mind and add tremendous value for them.

Once you have a deep understanding of what drives your customer’s decision-making process, you have an invaluable asset at your disposal: the ability to craft products and services that stand out in a crowded marketplace!

Define Your Manufacturing Process

A manufacturing process is a series of steps used to convert raw materials and components into finished products. This process can involve many different activities, including product design, material selection, machining, and assembly.

A good manufacturing process will maximize efficiency while maintaining quality standards. For example, product designs should be as efficient as possible in order to reduce waste, minimize tooling costs and achieve faster throughputs.

As of right now, the ERP manufacturing module is one of the best modules for manufacturing purposes out there.

The right materials should also be selected that are durable enough to withstand the necessary conditions yet not too expensive. Machining should be precise with minimal tolerance stacking in order to increase part fitment accuracy while reducing scrap rates.

And finally, the assembly should be a well-defined and repeatable procedure with integrated error-proofing methods in order to reduce errors during production and increase safety for both manufacturers and customers alike.

By carefully defining your manufacturing process in this manner, you can ensure an effective balance of quality and cost for all of your products.

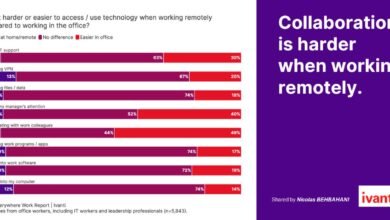

Select the Right Technology for Your Process

Technology has become an integral part of any business’s success, from small operations to larger organizations. For that reason, it’s essential to select the right technology for your process or organization in order to find the perfect balance between functionality and cost.

There are many different types of technologies available, so it can be overwhelming trying to narrow down your options. Fortunately, there are a few steps you can take to help ensure you choose the right technology for your needs.

Firstly, consider your operational goals and identify key features that will allow you to achieve these goals.

Secondly, evaluate each technology option based on factors like cost-effectiveness, scalability, and ease of use. Thirdly, make sure the chosen technology offers customization options that can be implemented easily in the future as needed.

Finally, assess how the technology will help maximize efficiency within your process and measure how much it adds value overall in terms of streamlining operations.

With these guidelines in mind, you can confidently select the best tech for today and build a framework for future growth.

Implement Quality Control Measures

Quality control is essential for any business that wants to succeed and meet the needs of its customers. Without effective measures in place, mistakes, miscommunications, and bad-quality materials will lead to problems and dissatisfaction with the end product.

This is why it’s important to have a plan in place to ensure high-quality results. Implementing quality control measures starts with a well-defined quality management system that outlines best practice standards and sets achievable goals.

Suppliers should be carefully chosen based on their ability to fulfill requirements, and worker training should include instructions on how to properly use materials, inspect items during production, document their findings, and report any issues they may come across.

Once these steps are carried out regularly with careful attention paid to detail, businesses can trust that their output will meet the highest standards of quality demanded by customers.

With a good plan in place to ensure success, any business can provide satisfactory solutions for those who seek them.

Train Your Employees on the Manufacturing Process

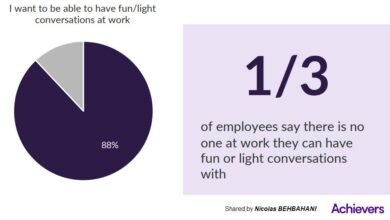

Training your employees on the manufacturing process is key to creating a successful and efficient production line. It allows your team to develop an understanding of the required abilities and strategies necessary to complete each step of the operation correctly, as well as become familiar with their respective roles.

It also reinforces safety protocols and enables them to troubleshoot any problems that may arise during the process. More importantly, it encourages collaboration between departments, fosters a sense of unity and respect for colleagues, and creates shared goals for everyone involved.

Investing in regularly scheduled training sessions for factory staff is essential for keeping efficiency levels high, customer satisfaction up, and employee morale positive.

Training personnel in the manufacturing process allows companies to be successful by having a knowledgeable workforce that works together with precision and focus. With comprehensive employee training in place, productivity will rise significantly throughout the whole production line while minimizing issues due to human error or misunderstandings.

Ultimately, successful implementation of such practices can increase profits in both short-term operational costs as well as long-term workplace satisfaction.

In conclusion, investing in employee training on the manufacturing process is invaluable when looking towards establishing a reliable and efficient production line.

Monitor and Improve Your Manufacturing Process

In any manufacturing environment, it is important to monitor and evaluate the process regularly in order to identify areas of improvement. The first step is to measure the performance of your processes.

By collecting data on various key indicators such as rework, errors, and waste ratios, you can then analyze the results to gain insights into how productive and efficient your process currently is.

Once the data has been gathered, it should then be used to inform the next step – identifying areas for improvement. This may involve technology upgrades or minor changes in operations and workflow, depending on what best fits the situation.

Finally, ongoing evaluation is essential – once improvements have been made, results should continue to be tracked closely in order to verify that they have achieved their desired effect.

Monitoring and improving your manufacturing process does take a significant amount of effort but following this approach will ensure favorable outcomes in terms of productivity and cost savings over time.

Conclusion

In order to create a successful product, you must first understand your customer’s needs and requirements. Once you have a clear understanding of what your customer wants, you can begin to define your manufacturing process.

It is important to select the right technology for your process and implement quality control measures to ensure that your product meets all of the necessary requirements.

Finally, it is essential to train your employees on the manufacturing process so that they are able to effectively execute it. By following these simple steps, you can create a successful product that will meet the needs of your customers.